2 ways to sharpen SDS chisel

2024-04-08 来自: 温州上钻工具有限公司 浏览次数:1100

1. Understand SDS chisels and their sharpening needs

SDS chisels are essential tools in masonry and construction work. This concrete chisel is designed for heavy-duty tasks such as chiseling, carving and breaking concrete, brick or stone. In order to maintain their effectiveness, when your SDS chisels show signs of reduced cutting efficiency, chipping or dulling, it is time for us to sharpen SDS chisels.

In this article we will give two methods of sharpen sds chisel.

2. Illustrated method for sharpening SDS chisels 1

For this method you need to prepare a whetstone and honing oil

Pick up your whetstone, one side of it is rough and the other side is fine. Starting on the rough side, add a little oil to the chisel whetstone.

2. What you need to do is balance the bevel edge of the chisel. After placing the bevel on the stone, hold the top of the chisel with your index finger and move it up and down, keeping your balance.

3. When you feel that the chisel is almost sharp, flip the stone to the fine side, add some oil, continue moving up and down, and repeat the previous movements to get perfect clarity and shine.

4. Finally, you need to remove the burrs on the back of the chisel edge. To do this, lay it sideways, flat on the stone, and run it across to remove burrs.

We also provide a reference video - from youtube(How to Sharpen a Chisel)by

blackwoodsau

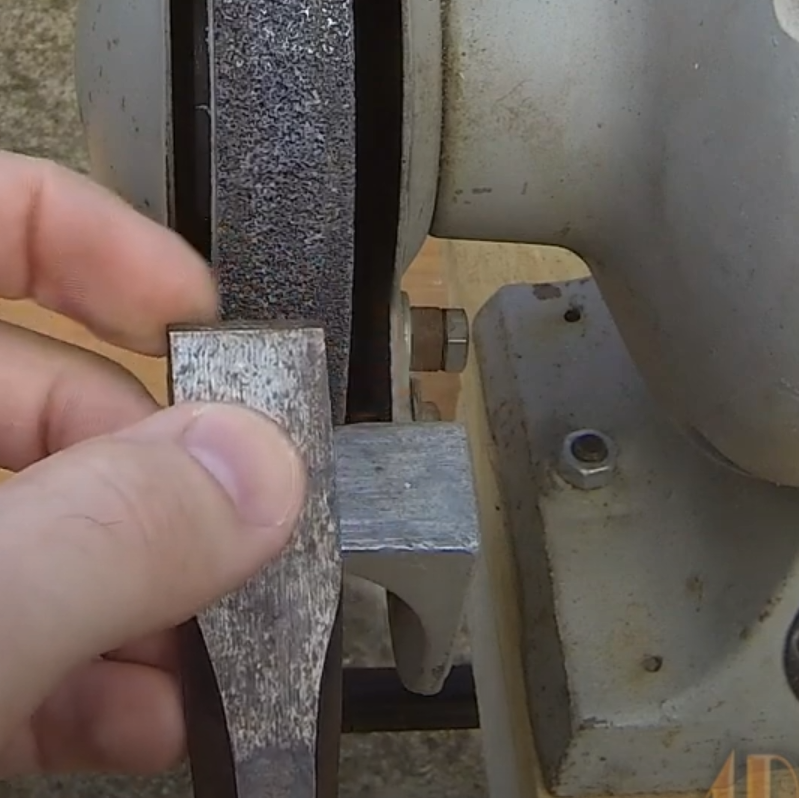

3. Illustrated method for sharpening SDS chisels 2

Tools/Supplies Needed:

-bench grinder

-metal chisel

-safety glasses

1. Prepare safety equipment: Make sure to wear safety glasses and gloves to prevent splashing debris from damaging your eyes and skin.

Prepare the bench: Place the bench grinder on a stable bench and make sure it is stable and will not slide.

2. Start grinding: Open the bench grinder and place the cutting part of the chisel gently on the grinding head, the degree should be about 60 degrees. Using gentle but even pressure, slowly move the chisel along the edge of the cutting edge. Remember to maintain steady hand movements to avoid irregular grinding.

3. Inspection and Testing: After finishing grinding, check whether the edge of the chisel is sharp. If necessary, additional grinding can be performed to achieve the desired sharpness. Finally, use the chisel to test its cut on the material to make sure it cuts as expected.

4. Cleaning and maintenance: After grinding, clean the chisel with a brush or cloth and apply a light layer of anti-rust oil to prevent rust.

We also provide a reference video - from youtube(DIY: How to Sharpen a Metal Chisel

)by 4diyers

4.How to choose a durable chisel

There are several factors to consider when choosing a durable chisel to ensure you are getting a tool that will meet the requirements of your job. Here are some guidelines to help you choose a durable chisel:

1. **Material Quality:** Look for chisels made from high-quality materials, such as high carbon steel or chromium vanadium steel. These materials offer excellent strength, durability, and resistance to wear and corrosion.

2. **Blade Hardness:** Check the hardness of the chisel blade, usually measured with a Rockwell hardness tester. The higher the hardness level, the better the edge retention and resistance to deformation during use.

3. **Made Quality:** Choose chisels from well-known brands known for their high manufacturing standards and quality control processes, such as Stanley, DEWALT, Irwin Tools, and DLTC from China. DLTC factory provides OEM processing for many big brands and has gained satisfaction and recognition from customers in many countries. A well-made chisel is less likely to develop flaws or weaknesses that affect its durability.

By considering these factors, you can choose a durable chisel that meets your needs and provides reliable performance for your woodworking or construction projects.